This adhesive is suitable for laminating substrates such as air duct materials, cable films, PET, and tinplate. It can be used with dry laminating machines operating at various speeds.

2 parts PU adhesive for air duct materials JT2250/GT2250

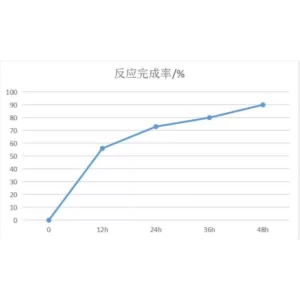

Polyurethane adhesive; Two parts PU adhesive; Laminating adhesive

Excellent ink affinity and coating performance.

Good bonding strength and flexibility for aluminum-plastic and copper-plastic composites.

Good chemical resistance and heat resistance.

- description

- Details

-

-

1.Technical data:

Product Modal JT2250 GT2250 Appearance Light yellow or yellow transparent viscous liquid Light yellow or yellow transparent viscous liquid Solid Content:(%) 50±2 60±2 Viscosity(cps/25℃) 1500±500 15-90 Smell No Smell No Smell Quality Ratio 20 2.5-3.5 2.Changes of reaction completion rate with aging time at 50℃

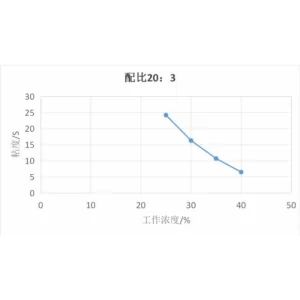

3. Solid content and viscosity change during dilution

solid content(%) 40 35 30 25 Main agent(kg) 20 20 20 20 Curing agnet(kg) 3 3 3 3 Ethyl acetate(kg) 6.5 10.7 16.3 24.2 - The water content of ethyl acetate shall not exceed 0.03%, and the alcohol content shall not exceed 0.02%. When the solvent contains active hydrogen (such as alcohol, amine), side reactions will occur, resulting in a decrease in the effective content of the curing agent. In actual use, the mixing ratio should be appropriately adjusted according to the situation.

4. Relationship between working concentration and viscosity at 25℃

5. recommend procedure

- Applicable machine models: Suitable for dry laminating machines of various speeds.

- The recommended ratio is 20:3 as the conventional ratio. The actual environmental humidity and printing ink have a significant impact on the composite effect. Customers should adjust the amount of curing agent appropriately according to the actual situation.

- Operating conditions: When diluting, add the solvent to the main agent according to the required solid content, stir thoroughly, then add the curing agent, and stir evenly before use. (Note: The water content of ethyl acetate shall not exceed 0.03%, and the alcohol content shall not exceed 0.02%. When the solvent contains active hydrogen (such as alcohol, amine), side reactions will occur, resulting in a decrease in the effective content of the curing agent. In actual use, the mixing ratio should be appropriately adjusted according to the situation.)

- Drying: In order to evaporate the solvent in the adhesive layer of the substrate film, the drying efficiency of the drying machine should be improved as much as possible.

- The required solid content of the glue is generally around (28-32)%. Customers should determine the solid content of the glue and the amount of glue to be applied based on the properties of the material being bonded, the performance of the rubber roller, and other conditions.

6.Glue amount

- The recommended coating amount is ≥2.0g/㎡ (dry basis). In actual application, customers can increase the coating amount appropriately according to the situation.

7.Maturing Condition

- The composite product should be cured in a curing room at (50±5)℃ for at least 48 hours.

8.Storage& Safety

- In a dry, clean, cool environment at 5-30℃, the unopened JT2250/GT2250 can be stored for 12 months.

- After contact with adhesive, you should thoroughly wash your work clothes, protective glasses, masks and gloves that are stained with glue;

- Be careful! Empty adhesive buckets also contain hazardous materials. Please follow the instructions on the adhesive bucket label and do not use the empty buckets without professional cleaning.

- If you need more safety information, please refer to our product safety data sheet.

9.Packing Info

- JT2250: 20kg/Drum, 200kg/Drum, 1000kg/Drum

- GT2250: 3kg/Drum, 20kg/Drum, 200kg/Drum

Product Categories

hot products