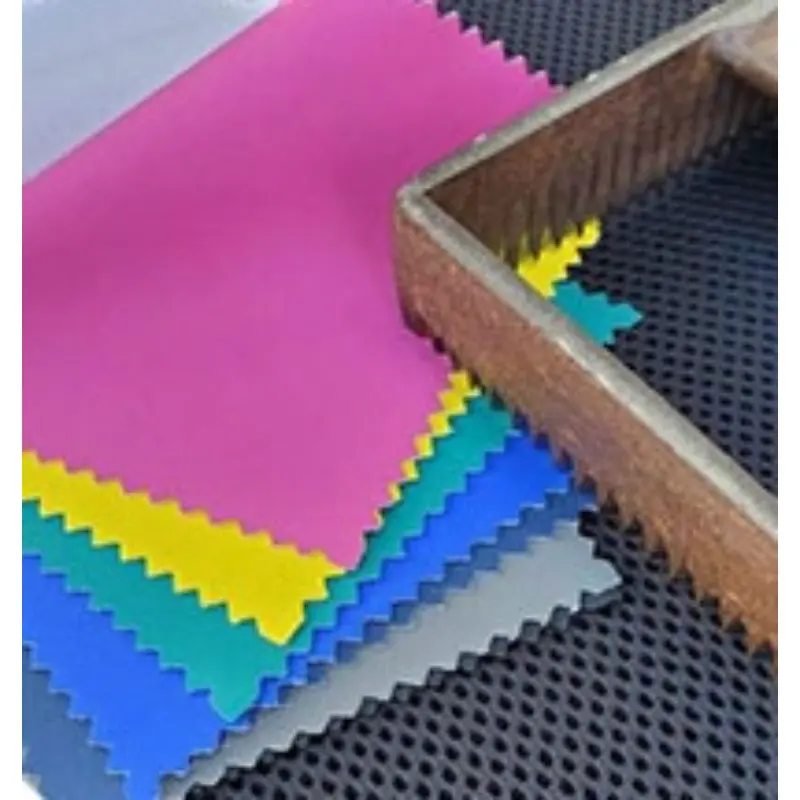

Reactive polyurethane hot melt adhesive is extensively employed in the lamination of fabric to fabric, providing strong, durable bonds essential for various applications in industries such as textiles, footwear, and automotive interiors. Its versatility and reliability make it a preferred choice for ensuring long-lasting performance and flexibility in fabric laminates.

Fabric-fabric lamination PU hot melt adhesive PUR3100

After curing, the reactive polyurethane hot melt adhesive demonstrates strong initial adhesion and bonding strength, along with outstanding resistance to high temperatures.

These properties ensure reliable performance in applications where durability and robustness are critical, such as in automotive manufacturing and industrial textiles.

- description

- Details

-

-

1.Data

Physical properties Data Solid content 100% Viscocity(cps/85℃) 6000±2000 Density(g/ml.85℃) 1.15 Smell No smell Appearance Viscous liquid 2.Recommended Technology

Open time ≥5min Coating temperature 100-120℃ Melt temperature 100-120℃ Coating methods Roller coating Glue amount The general coating amount is 10-20 g/㎡, for reference only. Preprocessing The substrate needs to be clean, dry and free of grease. For low surface energy substrates, corona or flame treatment may be required. Preparation before gluing Please prepare the glue melter, heating plate, feed pump and discharge gun, and set the appropriate temperature. Excessive heating will cause the adhesive to decompose. It is recommended to use it below 130 degrees. Users who use glue melt tanks must use nitrogen for protection. The humidity of nitrogen must be below 5ppm, otherwise it will accelerate the formation of skin. After opening the package, please use it up as soon as possible. Curing conditions In order to achieve complete curing, the compounded product can be stored at a suitable temperature and humidity (e.g. 25°C and 50% RH, or above). Under suitable conditions, curing will be completed within 7 days. At lower temperature and humidity, it will take longer to achieve complete curing. 3.Storage and safety

- In a dry and clean environment at 5-30℃, the shelf life of the original unopened product is ≤9 months. The opened but unused product should be used up as soon as possible.

- Be careful! Empty containers of adhesive also contain hazardous materials. Please follow the instructions on the container label and do not use empty containers without professional cleaning.

- If you need more safety information, please refer to our product safety data sheet.

4.Packing data

PUR3100:20KG/Drum OR 200KG/Drum

5.Regulation

Complies with the provisions of the US Food and Drug Administration FDA CFR21.175.105

Complies with the national standard GB 9685 Hygienic Standards for the Use of Additives in Food Containers and Packaging Materials related to adhesives

Complies with the national standard GB 9683 Hygienic Standards for Composite Food Packaging Bags related to adhesives

Product Categories

hot products