JY1130/GY1130 exhibits excellent mechanical processing performance, resulting in composite products with high bonding strength. These composites are characterized by their clarity and elasticity, as well as their resistance to aging and lack of odor. They also offer notable flexibility, water resistance, wear resistance, and resistance to dilute acids and grease. Additionally, the product remains usable without freezing at temperatures as low as -6℃ during winter. Furthermore, it demonstrates strong insulation properties.

B-level Insulation adhesive non-woven fabric and film composite JY1130/GY1130

Two-component insulation adhesive polyurethane adhesive

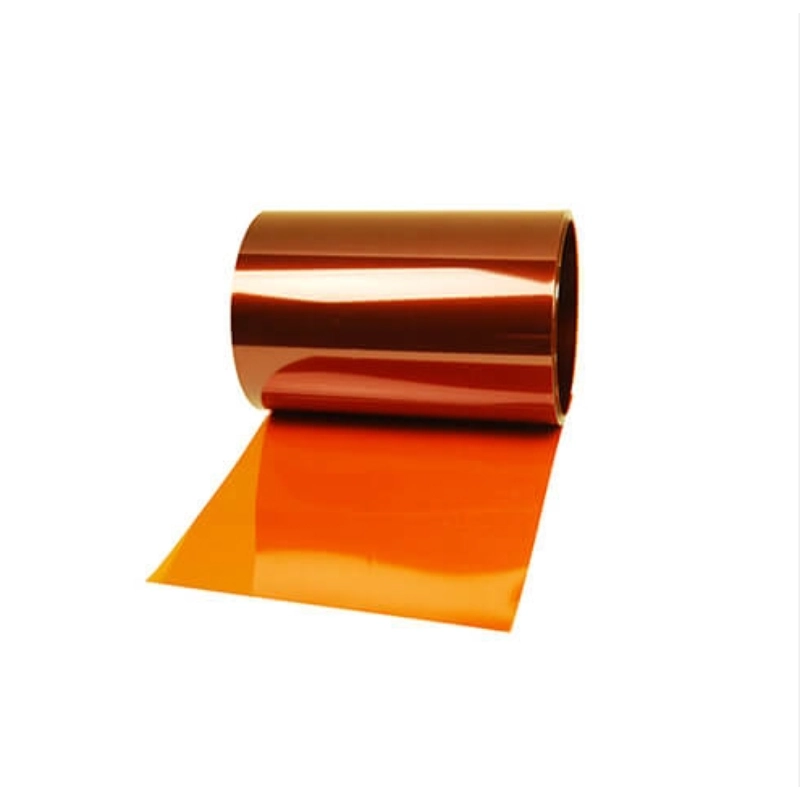

This technology can be effectively utilized for lamination between polyester film, highland barley paper, and non-woven fabric. By combining these materials through lamination, we can create composite products that benefit from the unique properties of each component. For instance, polyester film offers durability and moisture resistance, while highland barley paper provides an eco-friendly, biodegradable option with a natural aesthetic. Non-woven fabric adds strength and flexibility to the composite structure. Together, these materials can be used in various applications, including packaging, crafting, and industrial uses, enhancing both functionality and appearance. The lamination process ensures a strong bond between the layers, resulting in a cohesive product that meets specific performance requirements.

- description

- Details

-

-

1.some basic technical datas:

Product Model JY1130 GY1130 Appearance Yellow or yellow transparent liquid Colorless or light yellow transparent liquid Solid content 30±2% 60±5% Viscosity 40-160S 15-90S Solvents Ethyl acetate Ethyl acetate Ratio 7-8 1 2.How to use

- Mixing Ratio:Main agent: curing agent: diluent = 7-8:1:3-5

- Thinner:Suitable diluents are ethyl acetate and acetone. The water content in the solvent should not exceed 0.1% and should not contain alcohol, amine

- dilution:According to the required working concentration, add ethyl acetate or acetone to component A and stir evenly, then add component B and stir thoroughly.

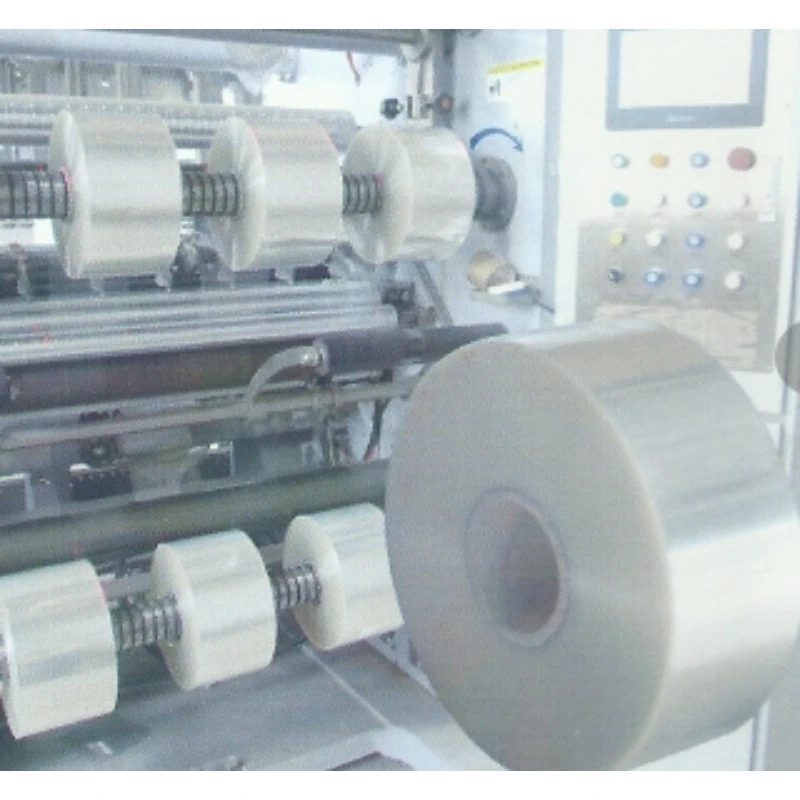

- Coating and coating amount:The coating is generally done by scraping with a steel wire (copper wire) roller. The coating amount can be controlled at (5.0-10.0) g/㎡ according to the material and requirements. The working concentration is generally (22-25)%.

- Composite method:The compounding is dry compounding, the drying oven temperature is (80-110)℃, the compounding temperature is controlled at (50-80)℃, and the compounding pressure is increased as much as possible without damaging the compounded product.

- Aging:In a curing room at 60-70℃ for more than 24 hours.

3. Storage

- At room temperature, the shelf life of JY1130/GY1130 in original unopened containers is 12 months

4.Precautions

- The amount of adhesive to be prepared depends on the needs.

- It should be prepared immediately before use.

- It is best to use up the prepared adhesive on the same day.

- The remaining adhesive should not be used in principle. If there is too much remaining adhesive, it can be diluted several times with solvent and placed in a sealed container.

- Store it in a cool and dry place. When working the next day, the remaining glue can be used as a diluent in small amounts (about 20% or less) and gradually mixed into the newly prepared adhesive (downgraded use). If it is found to be turbid, translucent, and viscous, it cannot be used anymore.

5.Package

- JY1130 :16kg/Drum or 180kg/Drum

- GY1130:4 kg/Drum or 20 kg/Drum

Product Categories

hot products