JY2130/GY2130 maintains excellent bonding performance even at 155℃. Once bonded, the film exhibits strength and resilience, being impact-resistant, vibration-resistant, oil-resistant, and capable of withstanding low temperatures. Additionally, it is resistant to water, dilute acids, and other media.

F-Level Polyurethane adhesive for laminated films JY2130/GY2130

Two component polyurethane adhesive for insulation lamination

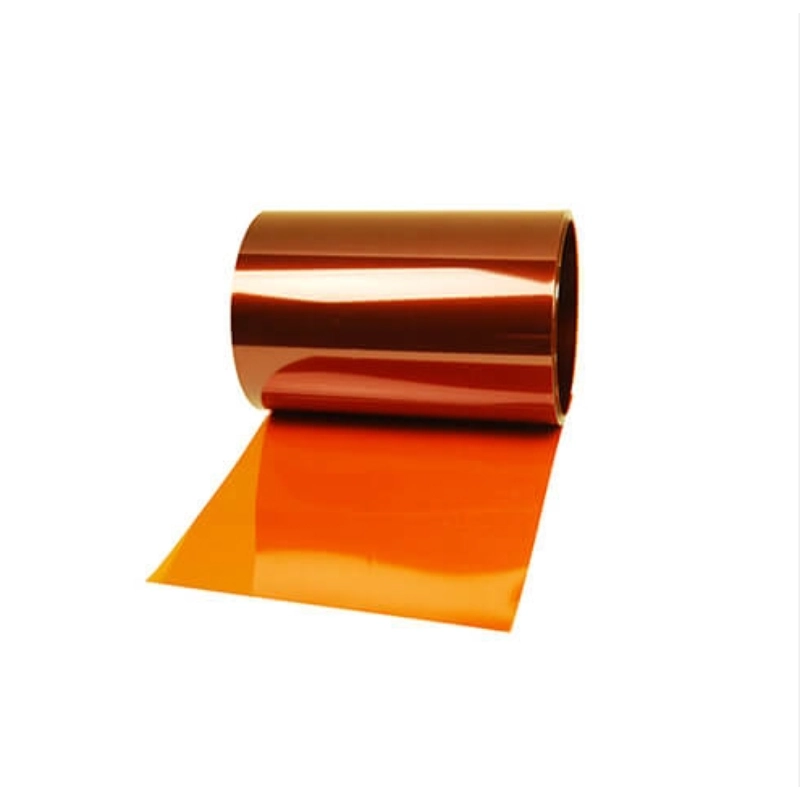

It can be used for lamination of materials such as polyester film, polyimide film, polyester fiber nonwoven fabric, etc.

- description

- Details

-

-

1.Technical data:

Product Modal JY2130 GY2130 Appearance Light yellow or yellow transparent liquid Colorless or light yellow transparent liquid Solid content 30±2% 60±5% Viscosity 40-160S 15-90S Solvents Ethyl acetate Ethyl acetate Ratio 7-8 1 2.How to use

- Mixing ratio: Main agent: curing agent: diluent = 7~8:1:1~4

- Thinner: Applicable diluents are ethyl acetate and acetone. The water content in the solvent shall not exceed 0.1% and shall not contain alcohol or amine.

- Dilution: According to the required working concentration, add ethyl acetate or acetone to component A and stir evenly, then add component B and stir thoroughly.

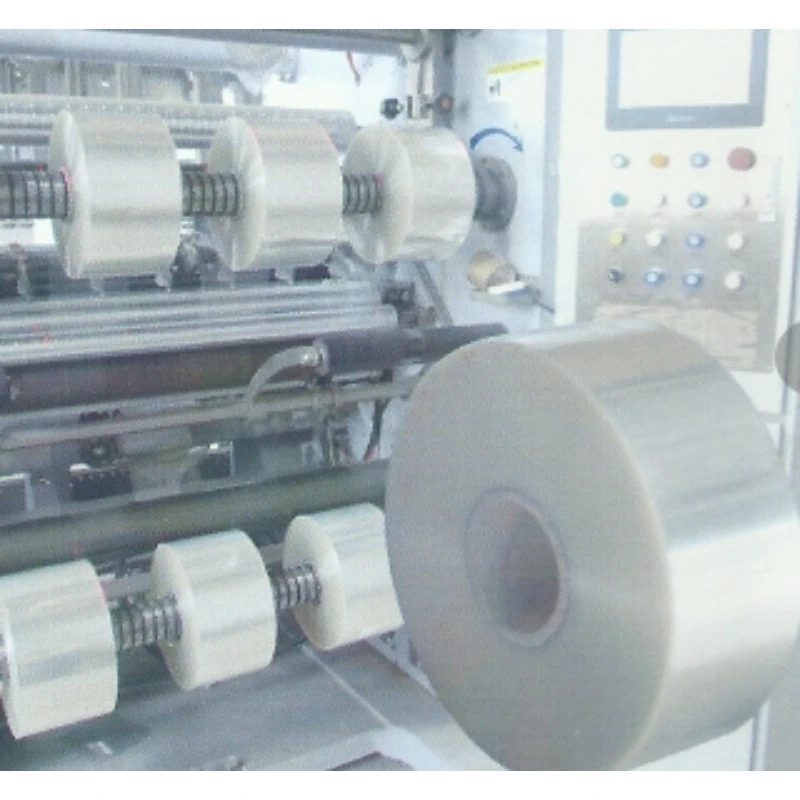

- Coating and coating amount: The coating is generally done by scraping with a steel wire (copper wire) roller. The coating amount can be controlled at (5.0-10.0) g/㎡ according to the material and requirements. The working concentration is generally (22-25)%.

- Composite method: The compounding is dry compounding, the drying oven temperature is (80-130)℃, and the compounding pressure is increased as much as possible without damaging the compounded product.

- Maturation: Curing room at not less than 70℃ for more than 24 hours.

3.Storage

- At room temperature, the storage period of JY2130/GY2130 in the original unopened container is 12 months. Once opened, please seal it in time and use up the remaining material as soon as possible.

4. Caution

- The amount of adhesive to be prepared depends on the needs. It should be prepared immediately before use. It is best to use up the prepared adhesive on the same day. The remaining adhesive should not be used in principle. If there is too much remaining adhesive, it can be diluted several times with solvent and placed in a sealed container and stored in a cool and dry place. When working the next day, the remaining adhesive can be used as a diluent in small amounts (about 20% or less) and gradually mixed into the newly prepared adhesive (downgraded use). If it is found to be turbid, translucent, and viscous, it cannot be used anymore.

5. Package

- JY2130: 16 kg/Drum or 180 kg/Drum

- GY2130: 4 kg/Drum or 20 kg/Drum.

Product Categories

hot products