The application cases of PUR adhesive (polyurethane hot melt adhesive) are very wide. Here are some specific application areas and their detailed cases:

Packaging industry:

In the packaging and reinforcement of cartons, PUR adhesive provides excellent bonding strength and can withstand the impact and vibration during the transportation of heavy objects. In addition, its moisture-proof properties ensure that good bonding effects can be maintained even in high humidity environments. It is widely used in the packaging of goods such as food and household goods.

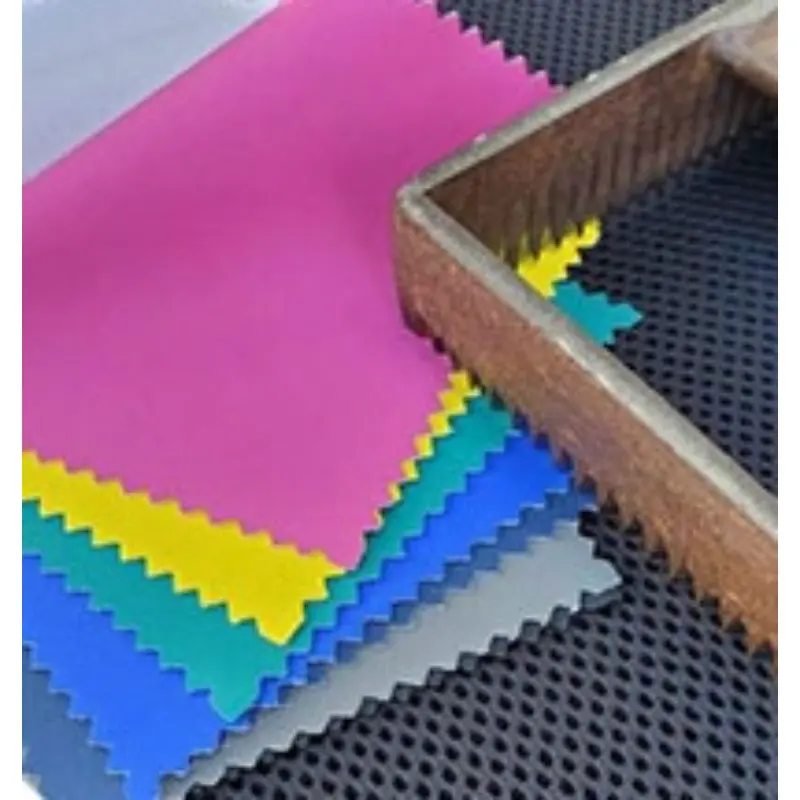

Textile industry:

PUR adhesive is used to bond different materials such as cloth, leather and synthetic materials in clothing manufacturing. It not only enhances the durability of the product, but also improves comfort and avoids the discomfort that may be caused by traditional sewing methods. This type of adhesive is particularly suitable for clothing that requires high elasticity, such as sportswear and outdoor equipment.

Woodworking industry:

In furniture assembly and wood connection, PUR glue is favored for its excellent durability and water resistance. Whether it is making kitchen cabinets or outdoor furniture, it can maintain stable performance in various climate conditions to ensure the long-term service life of the product.

Automotive industry:

PUR adhesive plays an important role in the bonding application of automotive interiors, such as the assembly of seats, door panels and dashboards. It can withstand the high temperature and vibration inside the car, ensure a strong connection between parts, and enhance the overall driving experience and safety.

Electronic assembly:

In the fixation and protection of electronic components, PUR adhesive can effectively absorb vibration and resist impact, ensuring the stability of circuits and components. It is commonly used in the production of mobile phones, computers and other consumer electronic products, and can maintain excellent bonding effects in various working environments.

Construction industry:

In the bonding and sealing of building materials, PUR adhesive shows excellent weather resistance and can withstand extreme temperature and humidity changes. It is widely used in the sealing of windows, door frames and walls to provide long-lasting protection.