Медный клей для фольги быстро становится популярным решением в системах HVAC для герметизации воздуховодов. Благодаря уникальному сочетанию термостойкости, защиты от коррозии и прочных адгезионных свойств он играет важную роль в улучшении производительности систем HVAC. В этой статье рассматриваются основные преимущества клей для медной фольги и почему это должно стать неотъемлемой частью обслуживания систем отопления, вентиляции и кондиционирования воздуха.

Что такое клей для медной фольги для воздуховодов?

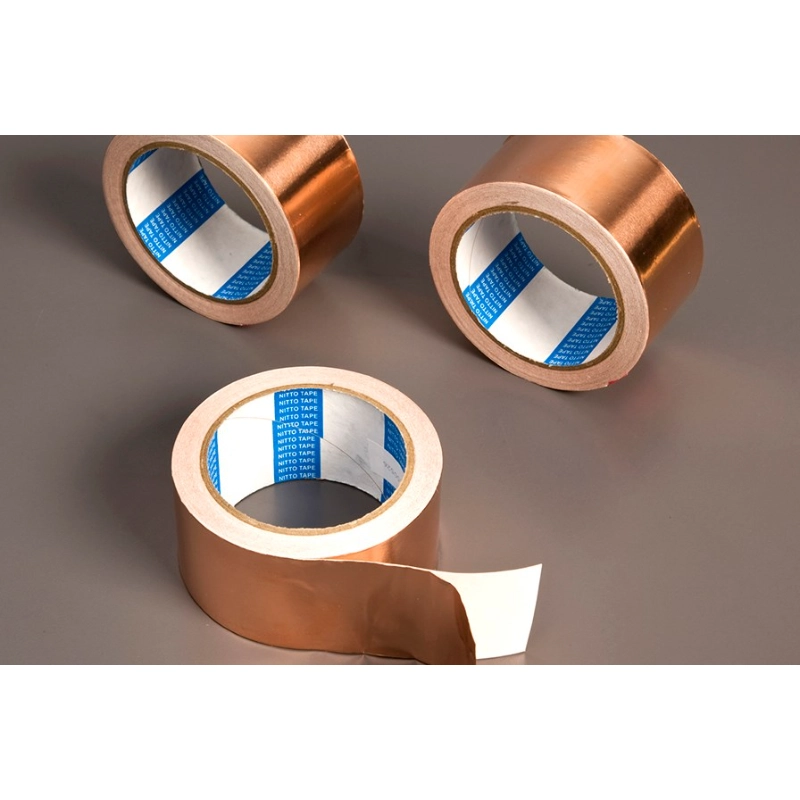

Клей для медной фольги — это специально разработанный материал, сочетающий в себе проводимость меди с высокоэффективный клей подложка. Этот клей используется в основном в системах HVAC для герметизации воздуховодов, обеспечивая их герметичность и эффективность. Его превосходная термостойкость и способность противостоять коррозии делают его высоконадежным материалом для долгосрочного использования в системах HVAC.

Основные преимущества клея для медной фольги для систем воздуховодов

1. Повышенная прочность и термостойкость

Клей для медной фольги славится своей превосходной прочностью, особенно в условиях высоких температур. Он может выдерживать экстремальные колебания температуры, что делает его идеальным для использования в системах HVAC, где воздуховоды подвергаются воздействию различных температур. Эта особенность гарантирует, что клей сохранит свои свойства с течением времени, что снижает необходимость в частом ремонте и замене.

2. Энергоэффективность за счет эффективной герметизации воздуховодов

Одним из основных преимуществ медного фольгированного клея является его способность эффективно герметизировать воздуховоды. Утечки в воздуховодах могут привести к значительным потерям энергии, поскольку кондиционированный воздух выходит, не достигнув места назначения. Герметизируя эти утечки медным фольгированным клеем, вы повышаете энергоэффективность вашей системы HVAC, что в свою очередь снижает затраты на электроэнергию.

3. Коррозионная стойкость для долговечных воздуховодов

Естественная устойчивость меди к коррозии делает ее отличным выбором для воздуховодов, подверженных воздействию влаги или высокой влажности. Это свойство помогает предотвратить ржавчину и ухудшение состояния, обеспечивая долговечность воздуховодов и снижая необходимость в дорогостоящем ремонте из-за коррозии.

Применение клея для медной фольги в воздуховодах

Клей для медной фольги универсален и может использоваться в различных системах отопления, вентиляции и кондиционирования воздуха, в том числе:

- Герметизация воздуховодов: Клей для медной фольги идеально подходит для герметизации воздуховодов, предотвращая утечки и обеспечивая плавный поток воздуха.

- Теплоизоляция: Его также можно использовать для изоляции воздуховодов, предотвращая потери тепла и обеспечивая эффективную работу системы отопления, вентиляции и кондиционирования воздуха.

- Защита от влаги: Медная фольга обладает высокой устойчивостью к влаге, что делает ее идеальным выбором для воздуховодов, расположенных во влажных или мокрых помещениях.

Как использовать клей для медной фольги при обслуживании и ремонте систем отопления, вентиляции и кондиционирования воздуха

Использовать клей для медной фольги просто, но он требует некоторой подготовки. Для правильного нанесения выполните следующие шаги:

- Очистите поверхность: Убедитесь, что поверхность воздуховода чистая и свободна от грязи, пыли или жира, чтобы обеспечить прочное соединение.

- Измерьте и отрежьте медную фольгу.: Отрежьте клейкую медную фольгу нужной длины, убедившись, что она соответствует площади герметизации.

- Нанесите клей.: Снимите защитную пленку с клея и приклейте ее к воздуховоду, плотно прижав для надежной герметизации.

- Сгладьте поверхность: Используйте разглаживающий инструмент, чтобы обеспечить равномерное нанесение клея и отсутствие пузырьков воздуха.

Почему клей для медной фольги — это разумная инвестиция для систем отопления, вентиляции и кондиционирования воздуха

Включение медная фольга токопроводящая лента клейкая в вашу процедуру обслуживания HVAC предлагает многочисленные преимущества, включая повышенную долговечность, термостойкость и энергоэффективность. Обеспечивая надлежащую герметизацию и защиту воздуховодов, вы можете продлить срок службы вашей системы HVAC, одновременно снижая потребление энергии. Независимо от того, имеете ли вы дело с новыми установками или ремонтом, клей для медной фольги является экономически эффективным и надежным решением.